SUGAR BEET DIGGER SV6F

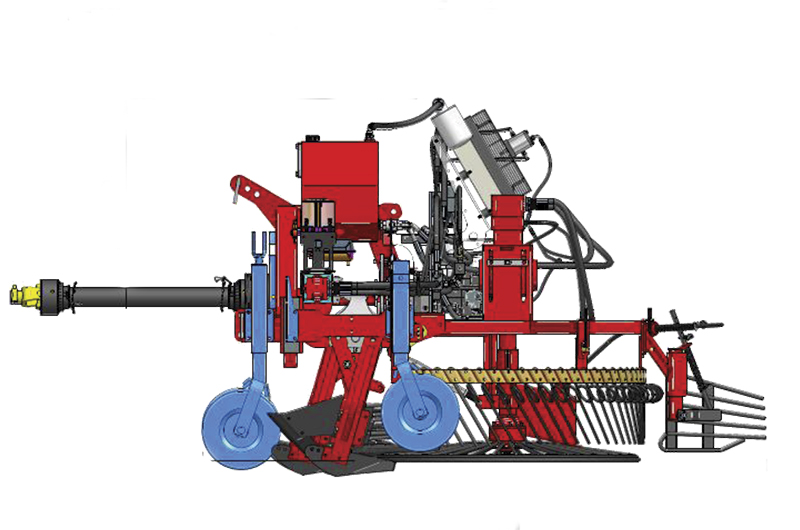

The sugar beet harvester SV6F H perfectly matches mechanical and hydraulic features. It is the result of the long company experience in the sugar beet harvesting with a cutting-edge hydrostatic circuit. It a very study unit but flexibly complying with any ground operating condition.

MAIN OPERATION

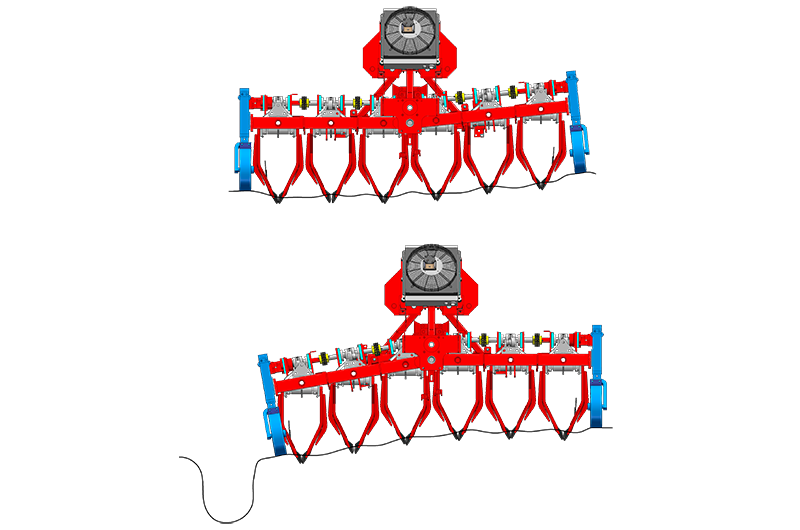

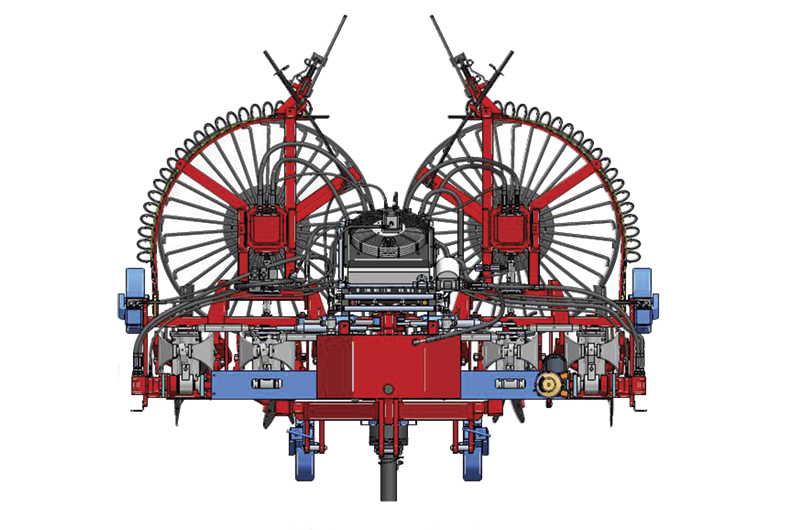

The sugar beet harvester removes the sugar beets from the ground and puts them into a single windrow, ready to be loaded. This machine is connected to the rear of the tractor by means of a third-point linkage and a drive shaft. The harvesting occurs on six interrows by means of vibrating ploughshares; the beets are then conveyed on two conveyor turbines that are used to remove the excess soil while creating the harvesting swath.

Versions

The unit is available in two different versions:

SV6F45H the unit works on 6 rows, 45 cm apart (maximum 3. m width)

SV6F50H the unit works on 6 rows, 50 cm apart (maximum 3.20 m width)

MAIN FEATURES

The unit stands out for its mechanical/structural and hydraulic features.

MECHANICAL FEATUREThe unit frame is entirely moulded and consistently made with high quality structural steels. The unit can stand traction loads up to 67 KN (about 200 HP) on the hard soils with no damage. However its not excessive weight is useful as the unit can work on wet soils as well. The frame is centrally jointed, thus allowing the unit to work on rocky and bumpy soils without increasing the digging depth, leading to less wear, less absorbed power and cleaner beets. The row distance is not changed when the machine stretches.

MECHANICAL ADJUSTMENTS

There are 3 adjustments to be considered:

- Increase or reduction the ploughshare opening, useful for bigger or smaller beets

- Independent adjustment of the row distance, useful in the case of beet displacement following treatment rotations

- Grid height, depth and bending of the conveying conveyor turbine

HYDRAULIC CIRCUIT

The unit is hydraulically operated and employes an independent hydrostatic circuit consisting of top quality tubes and parts. As for the circuit to be operating, connect the universal joint to the tractor PTO at 1000 rpm, and the control gear box to a 12V power socket. The beet harvester is fitted with two variable capacity piston pumps controlling and turning the conveyor turbines up to a 3800 N.mt twisting stroke each. The other two auxiliary pumps control the vibrating motors, the radiator and the actuators. A consistent attention was paid to temperatures: heat developing from the hydraulic circuit never rises higher than 30°. Therefore, even in case of very high external temperatures, e.g. 40°, the oil temperature will never be higher than 70°, well under the 90/100° limit when it is not longer usable. The hydraulic circuit allows to lower costs in terms of wear, up to 70% in comparison to the previous mechanical version.

HYDRAULIC ADJUSTMENTS

Controls activated from the tractor are:

- ON-OFF vibrations

- ON-OFF conveyor turbines

- ON-OFF greasing

- ON-OFF radiator

- UP-DOWN level wheels

REGULATIONS AND CERTIFICATIONS

The reference safety regulation is the machine directive 2006/42/CE The reference building regulation is UNI 13140:2010 The machine complies with original non preferential requirements for products manufactured in Italy reg. 2913/92 L The machine complies with original preferential requirementsfor products manufactured in UE “EUR1” reg. 2454/93

TECHNICAL DATA and CONNECTIONS

| SV6F45H | SV6F50H | ||

| Width | MT | 3.0 | 3.14 |

| Length / Length without doors | MT | 2.58 / 2,10 | |

| Height | MT | 1.66 | 1.38 |

| Empty weight | KG | 2200 | 2250 |

| Max absorbed power | KW/CV | 60 / 81 | |

| Max operating depth | MM | 250 mm | 2.8 |

| Turbine max revs | RPM | 150 | |

| Max turbine revs | Nmt | 3800 cad | |

| Max vibration revs | RPM | 520 | 50 |

| Max vibration stroke | Nmt | 360 cad | |

| Take-off revs | RPM | 1000 | |

| Oil tank | LT | 90 | |

| Oil | ISO | 68 HV | |

| Power supply | Volt | 12 (bipolar) | |

| Hydraulic supply | Gas | 1/2" floating | |

| Grease | TYPE | EP0-EP1-EP2 | |

| Connection category | CAT | 3° | |

| Row distance | CM | 45 | 50 |

OTHERS OPTION AND DETAILS

- Articulated Joint

- Standard universal joint

- oarse pitch conveyor turbine

- Narrow pitch conveyor turbine

- Open conveyor turbine