DEFOLIATING MACHINE DE6F

The defoliator is designed to chop sugar beet leaves. The machine is composed by a sugar beet leaves cutting rotor, a special screw conveyor transferring the product in a chopping unit that further cuts it and drops it through a tube.

A roller is placed inside the machine to avoid a possible obstruction. A special spreader disc spreads uniformly the leaves on the ground. The blades placed at the back of the machine are used for removing the beet collar.

THE UNIT IS AVAILABLE IN THREE VERSIONS:

The defoliator can be supplied in three different versions:

DE6F45 is a model used to work 6 rows at the same time, 45 cm apart (maximum length 3.16 m)

DE6F50R is a model used to work 6 rows at the same time, 50 cm apart (maximum length 3.2 m)

DE6F50 is a model used to work 6 rows at the same time, 50 cm apart (maximum length 3.4 m)

MAIN FEATURES

The unit stands out for the following features: it is a sturdy robust unit but lightweight at the same time. The unit is entirely screwed and each part can be easily replaced. Being so light, it can be front coupled to the tractor but, upon request, it can also be coupled on the back of the tractor, or to a tractor with reversed driving position. The rotor is fitted with impellers, which are so shaped as to provide a consistent suction. The front bonnet of the defoliating machine is made of high quality wear proof Hardox steel, providing the best durability in any possible operation. The rotor is fitted with 3 type C belts which, when correctly stretched, provide for the best traction and silent movement.

The conveyor belt is fitted behind the rotor, in a special casing. The casing is covered in polymer to cut friction and protect the sliding parts from wear. The belt is reinforced at the end to protect it from wear. The belt is fitted with a ratchet limit switch as safety system, preventing any accidental break in case of abrupt clogging caused by foreign bodies. The laterally ejected leaf parts are transferred side to the unit or spread uniformly on the ground. The cutting height is adjusted by means of a cylinder being directly connected to the hydraulic circuit of the tractor. To improve any collection activity, scalpers can be used for topping the beet collar. An all-in-one lubrication system allows to grease the unit from a single point. It can be connected to an automated pump as well.

REGULATIONS AND CERTIFICATIONS

The reference safety regulation is the machine directive 2006/42/CE The reference building regulation is UNI 13140:2010 The machine complies with original non preferential requirements for products manufactured in Italy reg. 2913/92 L The machine complies with original preferential requirementsfor products manufactured in UE “EUR1” reg. 2454/93

TECHNICAL DATA and CONNECTIONS

| DE6F45 | DE6F50R | DE6F50 | ||

| Width | MT | 3.16 | 3.20 | 3.36 |

| Length | MT | 2.63 | 2.63 | 2.63 |

| Height | MT | 1.38 | 1.38 | 1.38 |

| Weight | KG | 1080 | 1120 | 1180 |

| Absorbed power | KW / CV | 44 / 60 | ||

| Cutting space | MT | 2.8 | 2.8 | 3.0 |

| Take-off revs | RPM | 1000 | ||

| Type of connection | CAT | 3° | ||

| Distance between rows | CM | 45 | 50 | 50 |

| DE6F45 | DE6F50R | DE6F50 | ||

| Width | MT | 3.16 | 3.20 | 3.36 |

| Length | MT | 2.02 | 2.02 | 2.02 |

| Height | MT | 1.30 | 1.30 | 1.30 |

| Weight | KG | 1000 | 1040 | 1100 |

| Absorbed power | KW / CV | 44 / 60 | ||

| Cutting space | MT | 2.8 | 2.8 | 3.0 |

| Take-off revs | RPM | 540 (1000 upon request) | ||

| Type of connection | CAT | 3° | ||

| Distance between rows | CM | 45 | 50 | 50 |

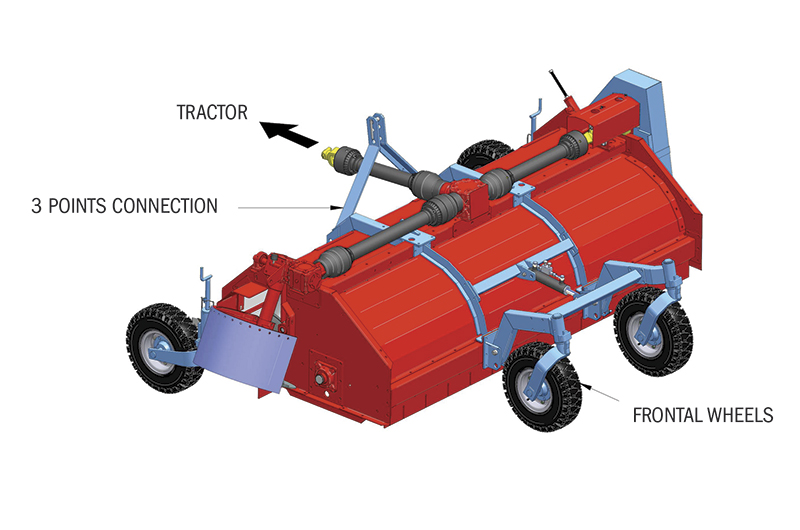

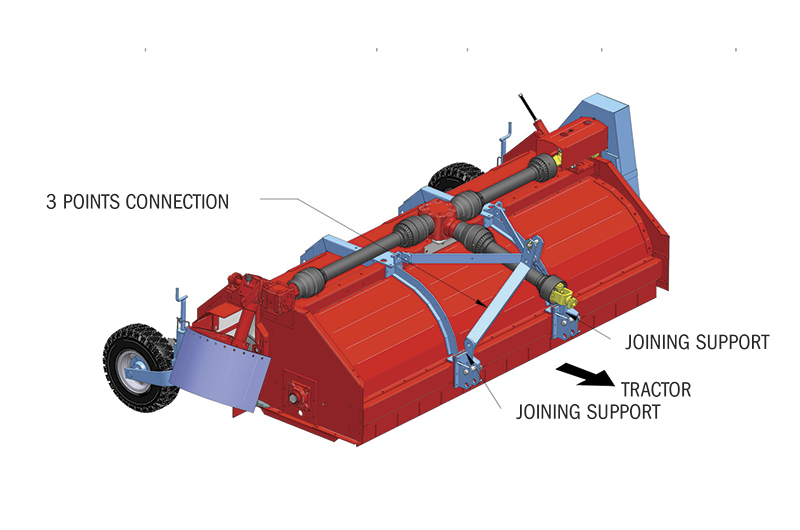

PUSH CONFIGURATION

The unit is connected to the tractor by means of a lifter and a front PTO. The hydraulic pipes for cutting adjustment are fitted to the front.

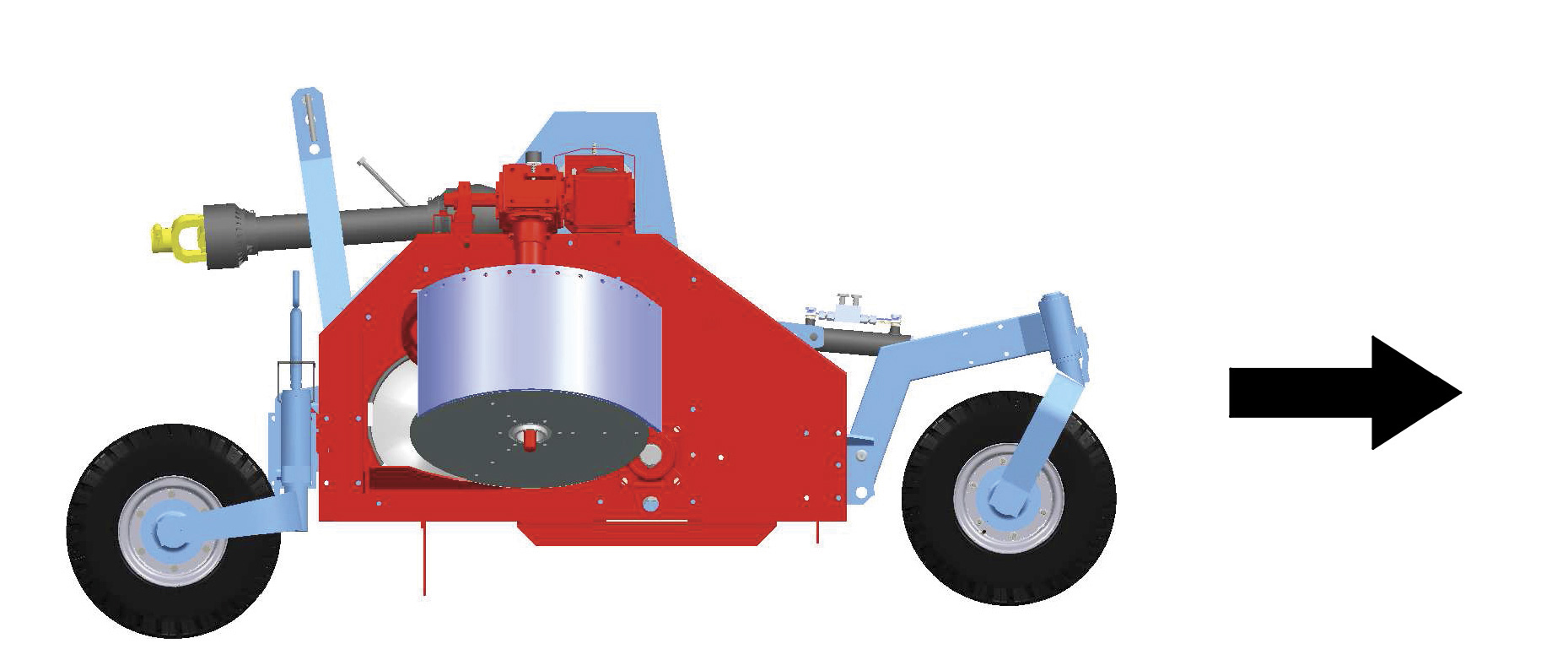

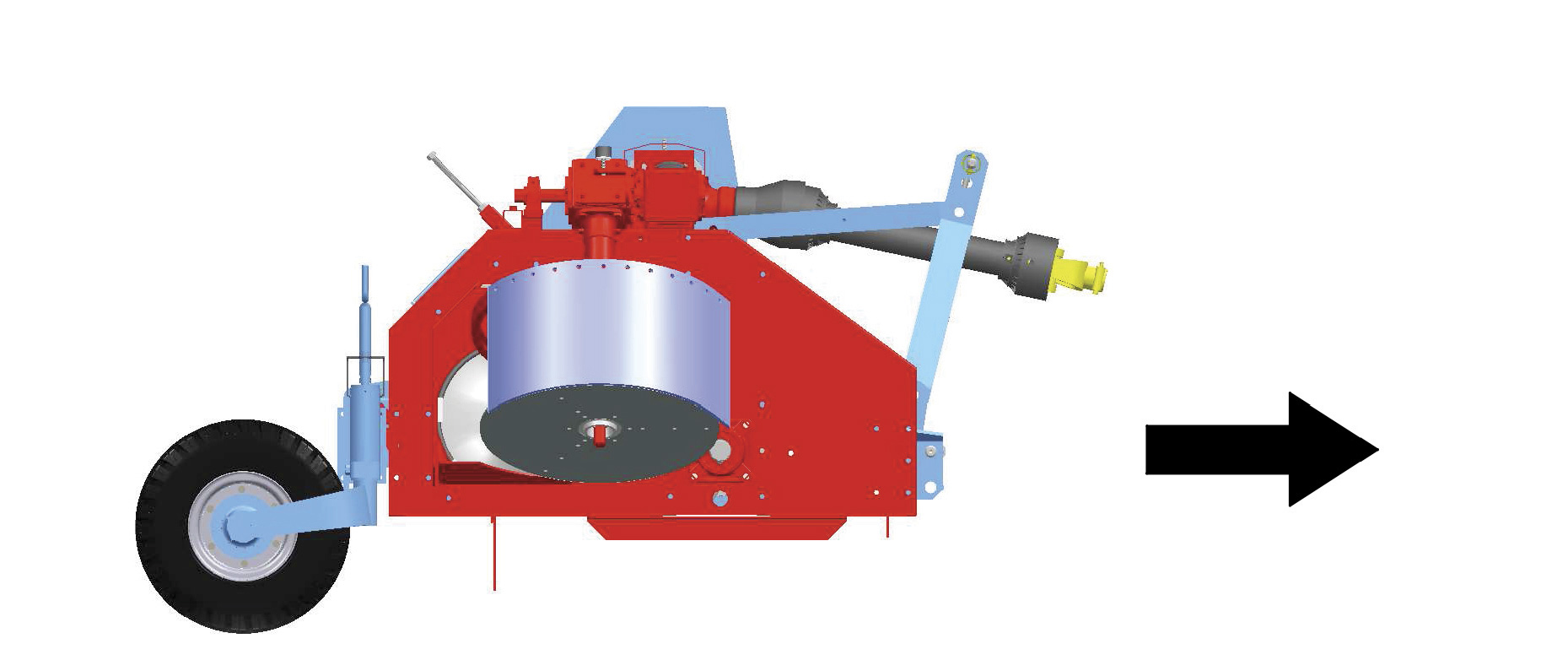

TOWED CONFIGURATION

The unit is connected to the tractor using the lifter and the back PTO. The cutting height is adjusted through the wheels and the tractor 3rd point.