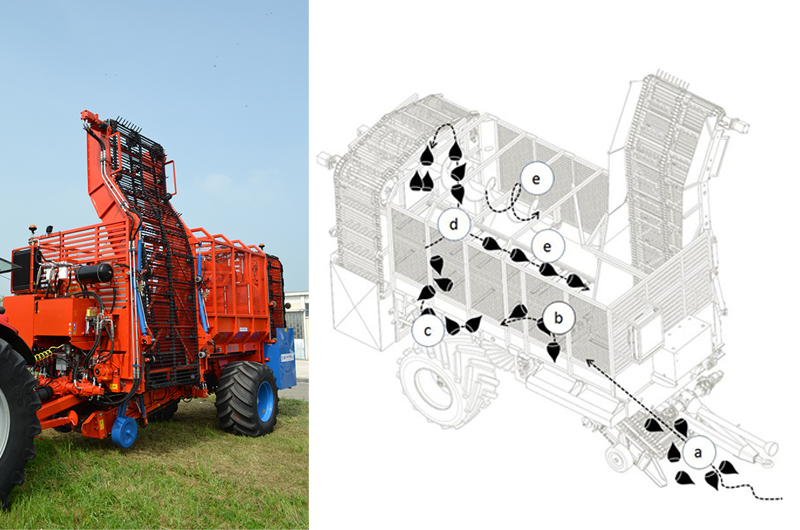

SELF LOADING WAGON AB 16 S

AB16S self-loading wagon is suitable for harvesting the beets with a single sugar beet harvester on a single raw. It has three different functions:

1. It collects the beets from the field.

2. It cleans the product removing grass, leaves and excess soil.

3. It moves the products besides the field or directly on the truck.

Beets are loaded through a steel belt or conveyed on two conveyor turbines. The collection belt consists of a highly resistant hardened steel chain and of a series of transversal bars, in hardened steel, transferring the beets. The unit is to be cleaned through the two conveyor turbines rotation and running thus removing soil and ground through friction and centrifuge strength. As an alternative, six cleaners can be fitted removing grass, leaves and excess soil. Both cleaning units are fitted under the frame.

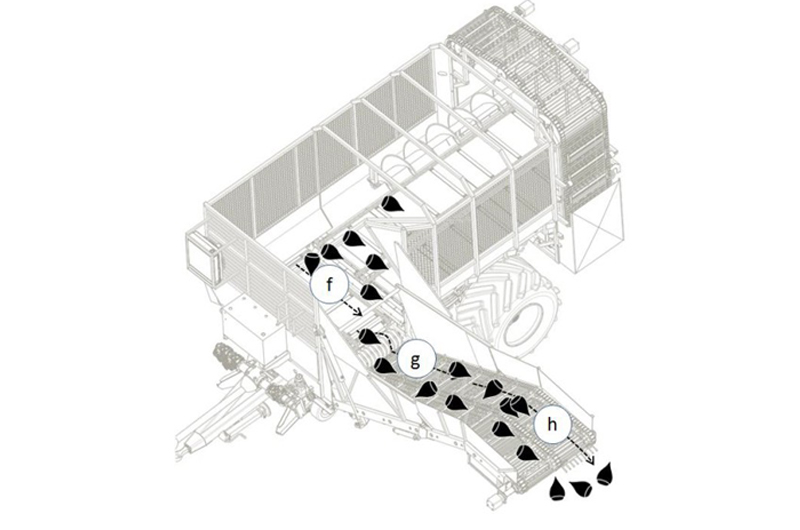

Once the beet connected, they are conveyed to the scoop by a conveyor belt: an auger fitted to the top homogenously spread the load inside the truck scoop. Once the scoop filled, move to the unloading area, beets are unloaded thanks to a side unloading belt and two overhead contact lines positioned on the flatbed, driving the beets inside the truck scoop. Once the unit unloaded, the belt folds.

MAIN FEATURES

As in the STACMEC tradition, the product building quality stands out. The AB16S self-loading wagon is made with top quality materials, based on consistent structural calculations, providing for the highest possible reliability under any operating conditions. The minimum safety coefficient used accounts for 1.8. High and wide wheels provide for the best soil floating. The empty mass accounts only for 7800 kg and its loading volume for about 20 cubic meters. With a single axle, the trailer is easy to move with small tractors as well, however it is possible to connect tractors up to 175 KW.

PARTS

All the commercial and hydraulic parts are manufactured by renowned manufacturers, standing out for their quality. This guarantees a capillary after-sale service in any country, and the ease of finding any product everywhere.

HYDRAULIC CIRCUIT

The trailer is hydraulically operated. The universal joints connected to the PTO tractor feeds the pumps. The circuit yield accounts for 92/94%. A closed loop system in fact it used, called hydrostatic, providing for high yields and low consumptions. The feeding pumps are calibrated to reach a maximum 315 bar pressure. The developed heat from the circuit running at full speed accounts for 15°C, while the maximum hydraulic circuit power accounts for 80 kW. On average, the loading phase absorbs 35 kW while the unloading one 52 kW. Collecting units are fitted with inverters, temporarily supporting the reverse movement in case of jamming. The motor speeds can be independently adjusted according to the driver requirements, the soil conditions or the type of tractor.

BRAKING

The trailer is fitted with a pneumatic braking system, with a release valve and CUNA standard connection.

OTHERS

Besides the standard parts, the trailer can be fitted with a centralized greasing system to improve and enhance rotary part operation.

REGULATIONS AND CERTIFICATIONS

The reference safety regulation is the machine directive 2006/42/CE The reference building regulation is UNI 13140:2010 The machine complies with original non preferential requirements for products manufactured in Italy reg. 2913/92 L The machine complies with original preferential requirementsfor products manufactured in UE “EUR1” reg. 2454/93

TECHNICAL DATA and CONNECTIONS

| Track width | MT | 2.9 |

| Minimum transportable width | MT | 2.5 |

| Length | MT | 7.4 |

| Maximum height on the road | MT | 3.9 |

| Empty weight | KG | 7800 |

| Loading capacity | M^3 | 20 |

| Unloading capacity | M^3 / min | 5-8 |

| Minimum unloading height | MT | 2.05 |

| Maximum unloading height | MT | 4.50 |

| Maximum unloading side distance | MT | 3.50 |

| Requested minimum power | KW/CV | 85/115 |

| Admitted maximum power | KW/CV | 175/240 |

| Take-off revs | RPM | 1000 |

| Oil tank | LT | 150 |

| Oil | ISO | 68HV |

| Power supply | Volt | 12 |

| Hydraulic connection | 1 x Float Min 1x Double effect |

1/2” BSPP 1/2” BSPP |

| Grease | TYPE | 0-2 EP |

| Pneumatic connection | TYPE | “CUNA” |

| Wheels | SIZE | 710/45 R26.5 |

LOADING

a. Collection with steel belt

b. Cleaning with conveyor turbines or rollers

c. Loading with lifting belt

d. Loading in the scoop

e. Load distribution through the auger

UNLOADING

f. Longitudinal load transport

g. Transverse load transport

h. Unloading on the ground or on a truck